Product Inspection Process for Aluminum Cylinder Heads

High-Quality Assurance from Raw Material to Final Packaging

1. Incoming Material Inspection

Aluminum Alloy Composition Analysis

- Use spectrometers to analyze the aluminum alloy grade (e.g., A356.2, AC4B)

- Check material certificates and traceability of furnace batch numbers

Auxiliary Material Inspection

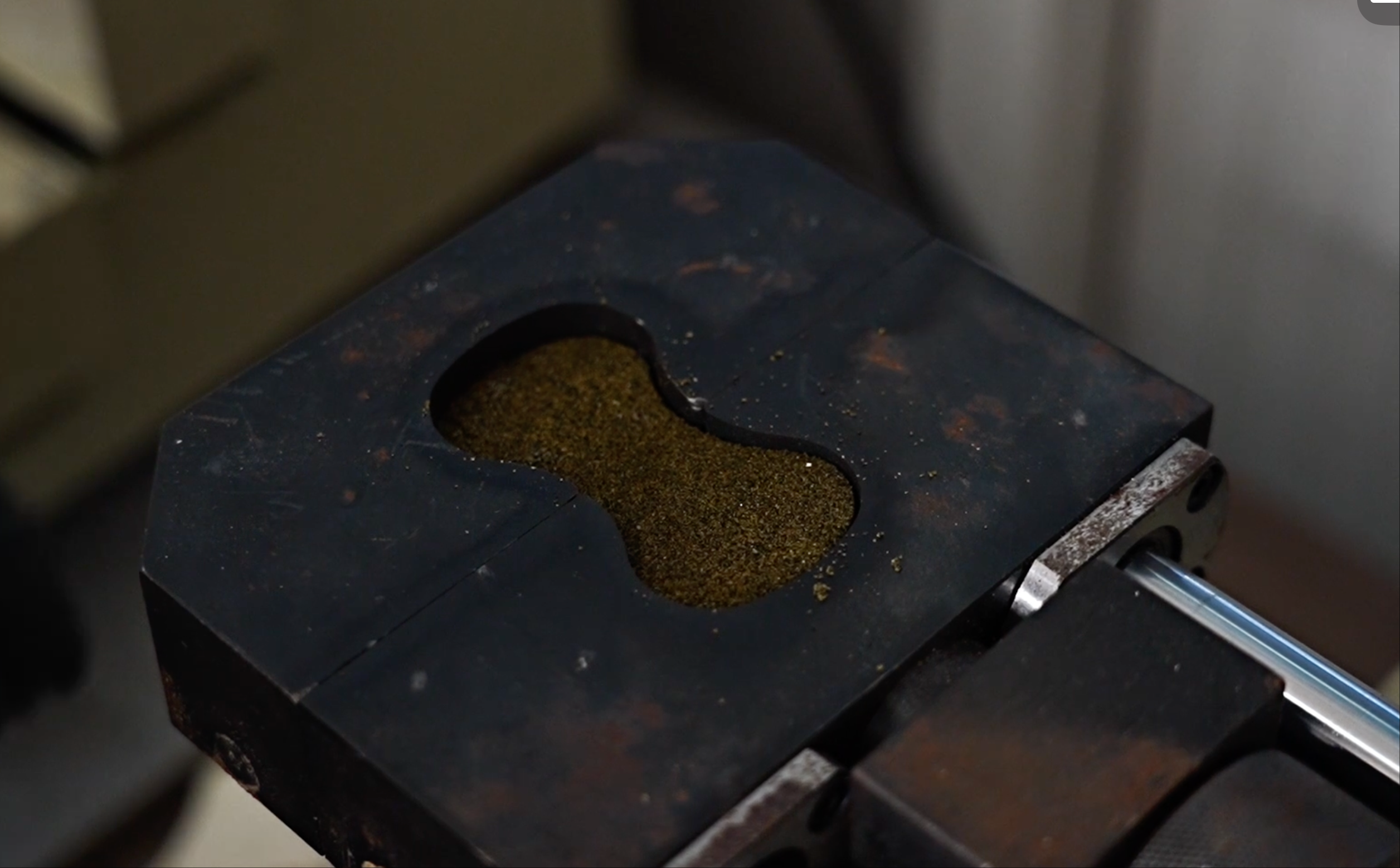

- Check batch numbers, appearance, drying quality, and flowability of coatings, sand cores, and chills

2. Post-Casting Inspection

Visual Inspection

- Check for porosity, slag inclusion, cracks, deformation, and cold shuts

- Verify the profile and dimensional completeness according to drawings

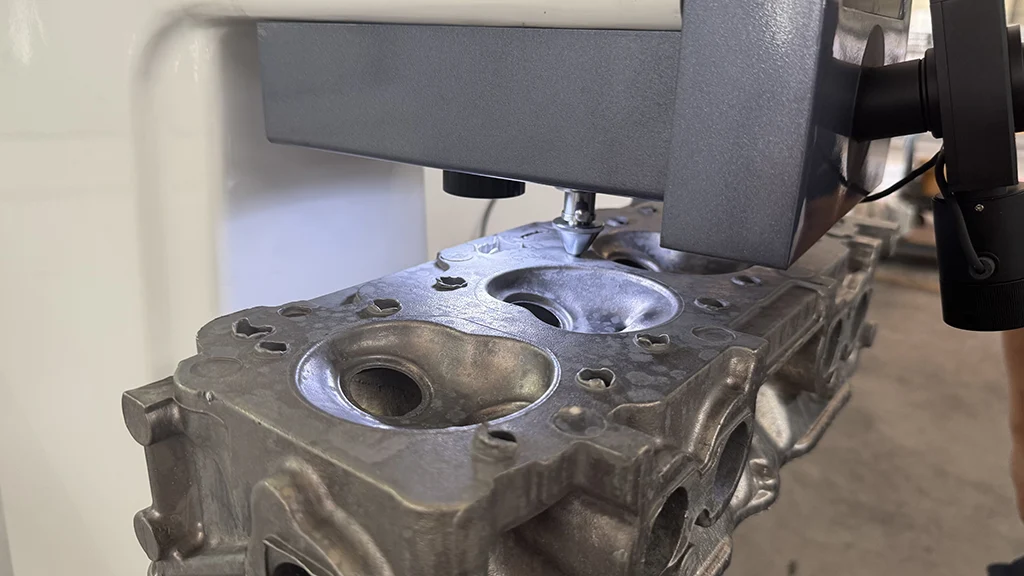

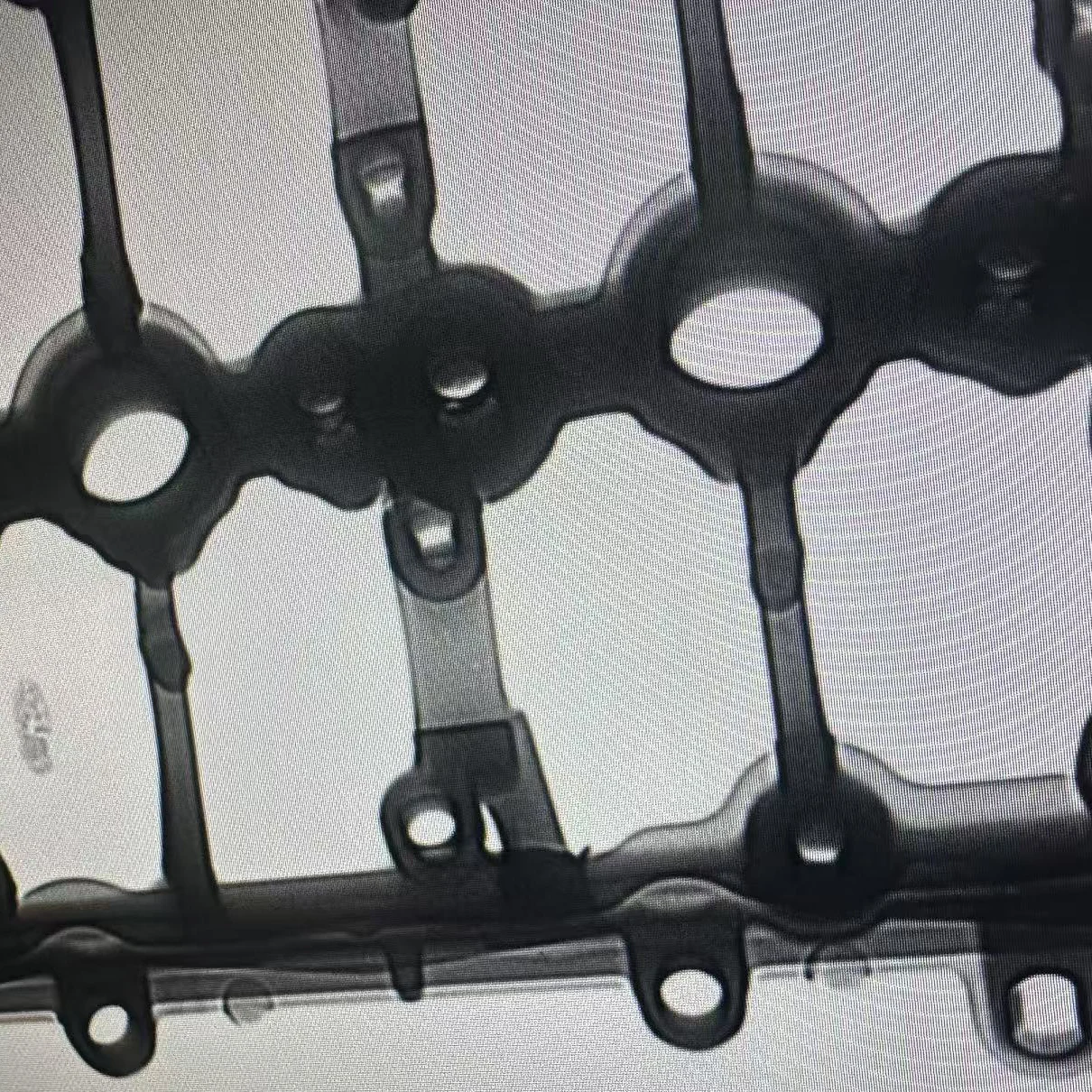

X-ray Defect Testing

- Conduct non-destructive testing (NDT) on critical areas like combustion chambers, water, and oil passages

- Evaluate internal defects such as shrinkage cavities, sand holes, and inclusions

3. Post-Machining Inspection

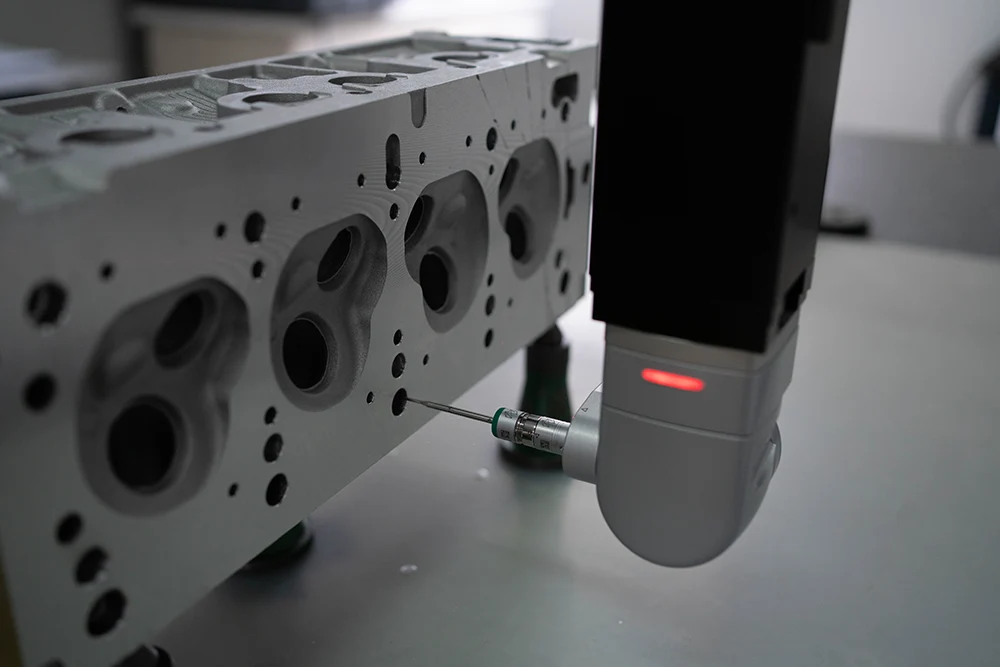

Dimensional Inspection

- Use CMM, calipers, and micrometers to check critical dimensions

- Inspect valve guide holes, valve seat bores, camshaft journals, and head flatness

Thread Hole Inspection

- Check threads with go/no-go gauges

- Ensure concentricity and thread integrity

Hardness Test

- Perform Brinell or Rockwell hardness testing to confirm heat treatment or natural aging results

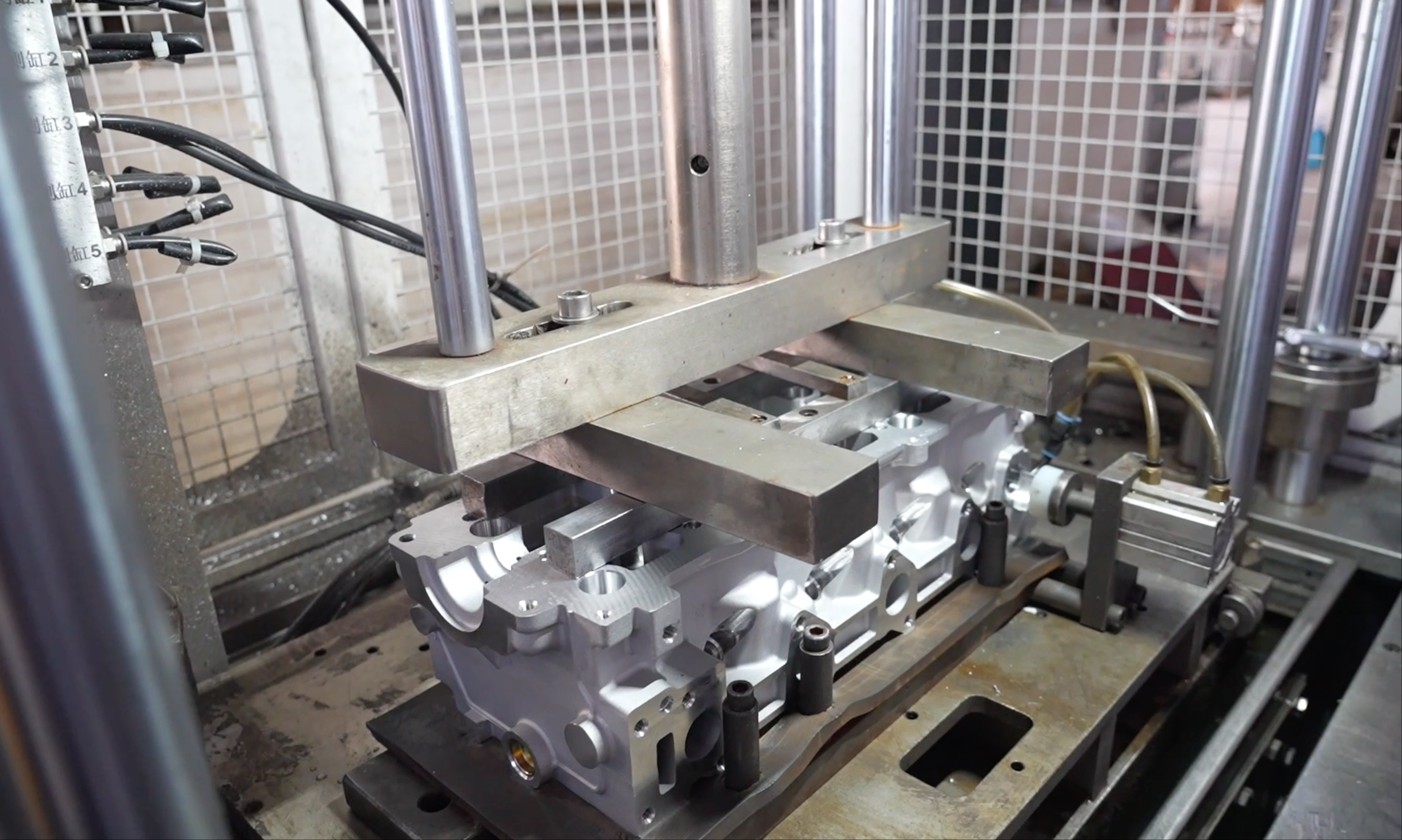

4. Leakage & Pressure Test

Water Jacket Air Pressure Test

- Inject 0.5-1.0MPa of air pressure, hold for 1 minute, and check for leaks or bubbles

Oil Passage Pressure Test

- Simulate oil pathways using fixtures, then conduct pressure holding and sealing tests

5. Final Appearance & Cleanliness Inspection

Cleanliness Check

- Inspect for residual metal chips or sand inside the casting

- Use endoscopes or cleanliness analysis devices to detect contamination

Surface Treatment Confirmation

- Verify deburring, sandblasting, passivation, and coating quality

- Check if labeling, batch number, and anti-rust protection are in place

6. Final Pre-Packaging Inspection

- Inspect product model, batch number, and accessory completeness as per shipping standards

- Verify traceability via QR codes, laser marking, or serial numbers

- Ensure packaging materials are clean, pressure-resistant, and moisture-proof

- Include certificates of conformity and packing list before shipment

Remarks

- One sample from each batch should be retained for traceability

- Inspection records must be archived for no less than three years

- Custom test plans available upon client request

Product assembly testing and road testing

1. Cylinder Head Assembly Testing Procedure

Pre-Inspection of Components

- Inspect valves, valve guides, valve seats, springs, oil seals, camshaft, and bushings

- Confirm material certificates and hardness test reports

- Ensure dimensional accuracy per technical drawings

Precision Assembly

- Install valve group (valve, spring, retainer, locks)

- Press-fit valve stem seals carefully to avoid damage

- Insert valve guides and check clearance (g., 0.02-0.05 mm)

- Perform valve sealing test (g., kerosene leak test or vacuum test)

- Assemble camshaft and bearing caps, tighten bolts per torque and sequence specs

- Adjust valve clearance if applicable

Dynamic Function Test

- Rotate camshaft manually to ensure smooth movement

- Check valve timing and spring return

- Perform pressure testing:

- Air pressure test

- Oil passage pressure test

- Run vacuum or pressure leak test on assembled head

2. Cylinder Head Road Test Procedure (for Aftermarket Units)

Trial Installation & Cold Start Check

- Install cylinder head assembly on engine using OEM torque sequence and specifications

- Fill coolant and engine oil

- Start engine cold, observe for eaks, abnormal noise, and idle stability

Warm-Up Test (Idle and Load)

- Bring engine to operating temperature ( 90-95°C)

- Test under idle and increased RPMs

- Monitor:

- Valve noise

- Valve clearance behavior

- Oil pressure and coolant temperature

- If no anomales after 20-30 minutes, proceed to road test

Road Simulation Test

Recommended Duration: 500-3,000 km (depending on project scope)

- Driving Conditions:

- Urban driving: Stop-and-go traffic, idle time

- Highway driving: Constant speed at higher RPM

- Uphill/High-load segments: Test combustion chamber temperature resilience

- Rapid acceleration/deceleration: Test oil supply, valve spring response

- Monitoring Points:

- Coolant and oil levels

- Smoke emissions (white = coolant, black = fuel, blue = oil)

- Unusual engine sounds

- Overheating or temperature spikes

- Check engine lights or OBD readings

Post-Test Disassembly & Analysis

- Remove the cylinder head and inspect:

- Valve and seat condition (burning, deformation)

- Valve guide wear

- Gasket impressions and sealing effectiveness

- Flatness of the head base

- Any signs of cracks, corrosion, or oil/water leakage